I. Technical conditions for ordering plywood for railway passenger cars

1.Overview

Plywood is a three-layer or more thin board made by peeling logs into veneers or planing wood into veneers and then gluing them together.

2.Related standards

GB9846.1~ 8-2004 Plywood

TB/T2402-1993 Flame retardant requirements for non-metallic materials for railway passenger cars

TB/T2560-1995 Selection requirements for non-metallic materials for railway passenger cars

Q/PC25-016-1996 Technical conditions for ordering plywood for railway passenger cars

Document No. 3 of Yunzhuang Passenger Car [2003] “Review of the study on the limits of harmful substances in the interior and interior materials of railway passenger cars”

“Technical conditions for the limits of harmful substances in the interior materials of railway passenger cars”

“Technical conditions for the limits of formaldehyde in the indoor air of railway passenger cars”

3.Dimension tolerance

3.1 Format size: 1220X2440

3.2 Tolerance requirements: The length and width tolerance of plywood is +2.5 (GB/T19367.1-2003)

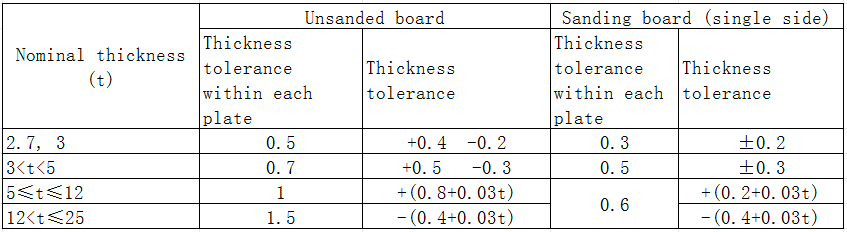

3.3 Thickness tolerance: (GB/T19367.1-2003)

3.4 Edge straightness tolerance GB/T19367.2-2003

The edge straightness tolerance of plywood is 1 mm/m.

3.5 Verticality tolerance GB/T19367.2-2003

The straightness tolerance of plywood is 1 mm/m.

3.6 Warp

The warp of plywood with a nominal thickness of more than 6 mm: the warp of superior products shall not exceed 0.5%

The first-class products shall not exceed 1%, and the qualified products shall not exceed 2%.

4.General technical conditions for ordinary plywood

4.1 Types:

4.1.1 The species of the plywood panel is the species of the plywood.

4.1.2 Ordinary plywood is divided into three categories:

Class I plywood, that is, weather-resistant plywood, is used under outdoor conditions and can pass the boiling test;

Class II plywood, that is, water-resistant plywood, is used under humid conditions and can pass the 63°C ± 3°C hot water immersion test;

Class II plywood, that is, non-moisture-resistant plywood, is used under dry conditions and can pass the dry state test;

4.2 Physical and mechanical properties

4.2.1 Moisture content

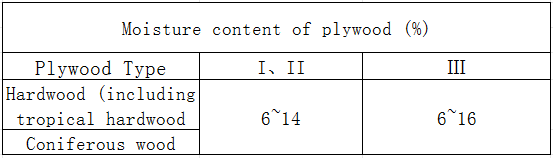

The moisture content of plywood when leaving the factory shall comply with the provisions of the following table:

4.2.2 When the average moisture content of the test specimens meets the requirements of Table 1, the moisture content of the batch of plywood is judged to be qualified; if not, re-sampling is allowed for re-inspection and re-judgment of whether it is qualified or not.

4.3 Bonding strength

4.3.1 The bonding strength index values of various types of plywood should comply with the requirements of Table 2.