The Benefits of Fireproof Marine Plywood

If you’re interested in the benefits of fireproof marine plywood for your next project, read on. Learn how fire-resistant plywood can help you build your boat without risking your life in a fire. This article will describe the different types of plywood and their benefits. Despite the similarities, fire-resistant marine plywood is still the best option for many projects. Its light weight and resistance to cracking make it easier to move.

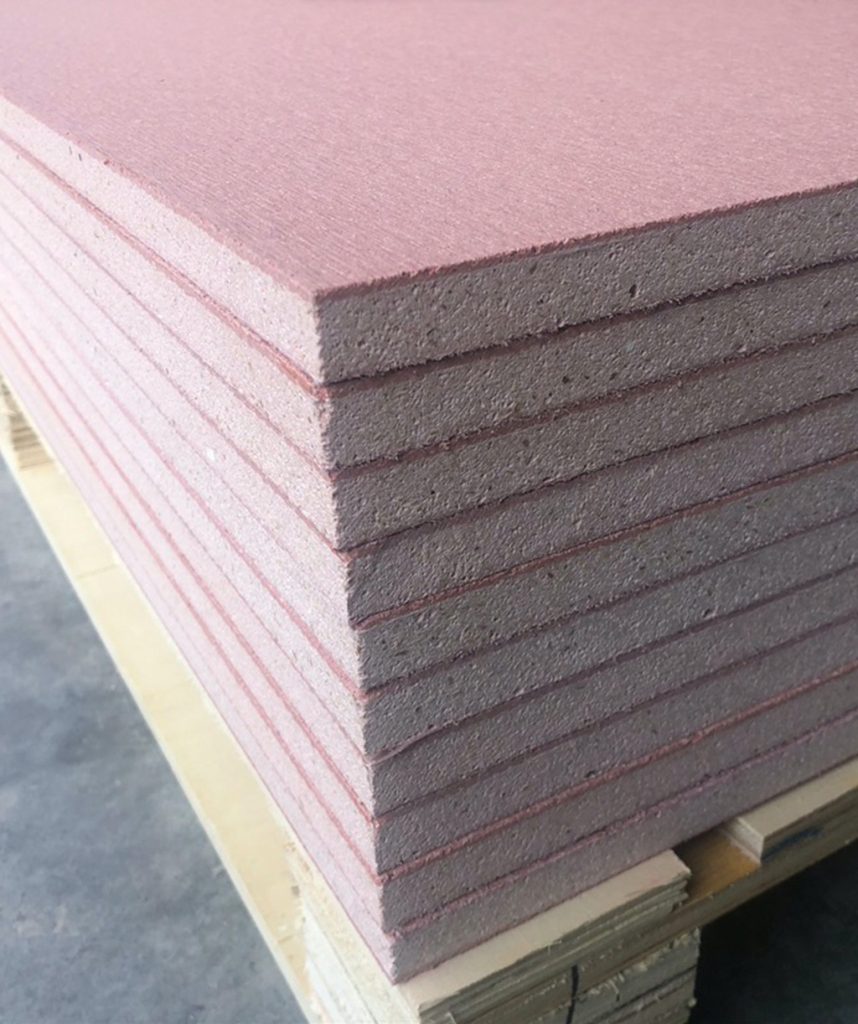

Fire-retardant plywood reduces spread of fire in buildings

If you want to build a home that’s safe from fire, you should use fireproof marine plywood. This type of wood can withstand high fire temperatures, and it can also withstand a variety of impacts. Fire can spread quickly and spread to nearby areas, so it’s important to know how to prevent it from spreading. There are a variety of types of fire-retardant plywood available.

Fireproof marine plywood, also known as FR grade plywood, is manufactured using chemicals that resist flame and borer damage. It can be used in homes, offices, and even car interiors. The fact that it doesn’t easily burn down makes it a popular choice for architects and other building owners. And, because it is chemically treated, it’s guaranteed against infestation.

While it’s not as strong as solid wood, fire-resistant plywood can be lightweight and easy to move around. And it’s more affordable than untreated wood, so you’ll likely save money on insurance. Another benefit to fire-resistant plywood is its ability to resist mold and insects. Fireproof marine plywood has many benefits over regular plywood. Listed below are some of the benefits of using this type of plywood.

Fire resistant treated plywood has been used in about a million housing units east of the Mississippi since its discovery several years ago. It’s so common that scores of lawsuits have been filed against manufacturers, suppliers, and insurers. One of the most notable examples of this is the Millponds town house development in Marlboro Township, N.J., which has roofs that are in various stages of decay. The discovery led E. Richard Kennedy to trace the issue to the wood itself.

It is lighter in weight

A better grade of marine plywood is not waterproof, but it is stronger and sturdier than regular plywood. This type of plywood is also a good choice for outdoor crafts, such as kayaks. It works well in both dry and wet environments, and can withstand extreme weather conditions. Besides being lighter in weight, marine plywood also holds up well under rough conditions. Compared to standard plywood, marine plywood is easier to work with and lasts for longer.

Choosing the right material for a project is important. A heavier product will cost more to ship. Likewise, lighter-weight furniture can reduce movement on the bottom. Fireproof marine plywood is also lighter in weight. However, it should be finished with a strong sealant to keep it protected from the elements. In addition, the weight will determine whether the product is strong enough to withstand a variety of situations.

Another important factor in choosing plywood for your project is bending capacity. Pressure-treated plywood can be bent over 18mm without damage. However, marine-grade plywood has a lower bending capacity than pressure-treated wood. While pressure-treated wood is lighter in weight, it is still heavier than marine plywood. However, the added weight is useful in hauling the piece of plywood over rough terrain. The added weight will be worth it, as it will ensure that the boat remains dry and safe.

Other factors include fire resistance. A/A grade of marine plywood is free of knots. It can be stained, painted, and sized on site. It is also void-free, meaning the surface will not be damaged when the boat hits it. The cross-layered structure of fire-proof marine plywood also makes it easier to cut and fasten it. Unlike other plywood types, this wood will not split easily when driven through.

It is easier to move

When you build a boat, the best type of plywood for your needs is marine-grade plywood. This type of wood is specifically engineered to withstand moisture, fire, and other natural elements. It is easy to move and assemble, and is stronger than ordinary plywood. It is also much easier to move than pressure-treated wood. Here are some advantages of marine-grade plywood. Read on to learn more. Fireproof marine plywood is easier to move.

Fireproof marine plywood is easier to move than regular marine-grade wood. While fire-retardant qualities are an advantage, they don’t negate the need to store the wood off the ground. Because of its cross-layer structure, plywood is easier to cut and is easier to move. It also does not split easily when driven through. The advantages of marine-grade plywood are many. But the downside is that it is heavier.

Pressure-treated marine plywood is more resistant to water. It is easier to move and assemble. However, it’s not completely waterproof and can leach chemicals. This is why you should buy plywood that has been treated with chemicals separately. The chemicals used in pressure-treated marine plywood make it more durable and stronger. And, as a bonus, it is easier to move. So, consider pressure-treated plywood for your boat!

Although untreated plywood is easier to work with, fire-retardant plywood is much heavier than normal wood. That’s why fire-retardant plywood is so easy to move and is more lightweight than its untreated counterpart. You can also buy fire-retardant marine plywood if you don’t want to use solid wood, as it’s much unwieldier and unreliable.

It resists cracking

Fire Retardant Marine Plywood meets or exceeds four ISI fire retardant standards. It is constructed from hardwood plantation timber and is impregnated with fire retardant chemicals before bonding. Aditya fire retardant marine plywood is resistant to cracking and breaking and is treated with thermosetting resins and micro organism resistant chemicals to resist water, fungus, and insects.

This marine-grade plywood has excellent fire retardant properties, but its bending capacity is poor. It cannot bend more than 18 mm before cracks appear. Continuous bending causes the layers to separate, resulting in a poor structure. Pressure-treated plywood is more flexible than marine-grade plywood. However, marine plywood is heavier than pressure-treated plywood, which is useful for hauling over rough terrain. Because it resists cracking and rotting, this type of plywood is best used for structures that require a stable surface.

Unlike exterior-grade plywood, fireproof marine plywood has no voids between veneer sheets. Unlike pressure-treated plywood, marine-grade plywood doesn’t require painting or polishing. It can resist cracking, but the grain pattern will be unsightly. Unlike pressure-treated plywood, marine-grade plywood has no voids. Hence, it is best to choose the latter type of wood.

While marine-grade plywood is more expensive, it is far superior to WBP-rated wood. In the most humid environments, phenolic-treated wood does not absorb water, whereas WBP-rated wood does. While WBP-grade plywood is more expensive than marine-grade wood, it is still more durable and resists cracking and knotting. The phenolic-treated wood has a smooth and glossy surface.

It is impregnated with chemicals

The Fire Retardant Marine Plywood meets all ISI standards for marine grade wood and is highly resistant to fire. It is manufactured from hardwood plantation timber and impregnated with flame-retardant chemicals before bonding. It is treated with micro organism-resistant chemicals and thermosetting resins to provide maximum durability even in the harshest conditions. Unlike ordinary pressure-treated plywood, Aditya Densified Plywood also has a unique chemistry that makes it highly resistant to flames and termites.

The open edges of the plywood panel are one of the simplest pathways for the fire retardant chemical to reach wood cell surfaces. However, moisture movement along the edges of the plywood board can make the chemical penetrate through the surface and cause significant deviations in fire performance parameters. The glue line also prevents moisture movement within the inner veneer layers. Therefore, fire retardant penetration through the surface of plywood panels is a problem, since it can extend much deeper than the top veneer layer, leading to large deviations in fire performance parameters.

The fire retardant chemicals added to the plywood during the manufacturing process delay the spread of the flame. This gives the victim time to escape and contain the fire. Furthermore, firefighters can easily participate in the rescue operations if the fire-proof ply is used in the building. The Austin Defender was introduced in response to recent fire accidents. The Austin Defender has a rating of four. This means that fire-resistant plywood is a great choice for boat builders.

The pressure treatment method of fireproof marine plywood incorporates the fire retardant deep into the wood cells. The pressure and chemical treatments change the chemistry of wood by making it less flammable. The flame front doesn’t progress much farther than 101/2 feet from the center of the burners. Additionally, the impregnated wood has a high level of durability that coatings cannot provide. The added benefit of fire retardants is that the chemicals are in the wood cells, and aren’t damaged during the construction process.