There are several common finishes used for custom furniture. These finishes should be chosen with care, because a poorly applied finish can tarnish a piece of furniture. Fortunately, custom furniture manufacturers have the expertise and experience to make your dream piece of furniture a reality. So what’s the best finish for your custom furniture?

1. Melamine veneer

Melamine veneer refers to a process in which a layer of melamine veneer paper is attached to the surface of the particle board, multi-layer board or MDF base material, and then the edges are sealed with PVC edge strips.

Melamine board is the most common board on the market, especially the particle board substrate with the most cost-effective melamine board. More than 80% of custom cabinets use this board, which can be used as both cabinet body and cabinet door. In addition to the most common wood grain, the pattern on the melamine board can be printed very clearly, and it is most suitable for modern furniture. The Austrian Eige board, which is popular all over the world, also belongs to the melamine board of the particle board substrate.

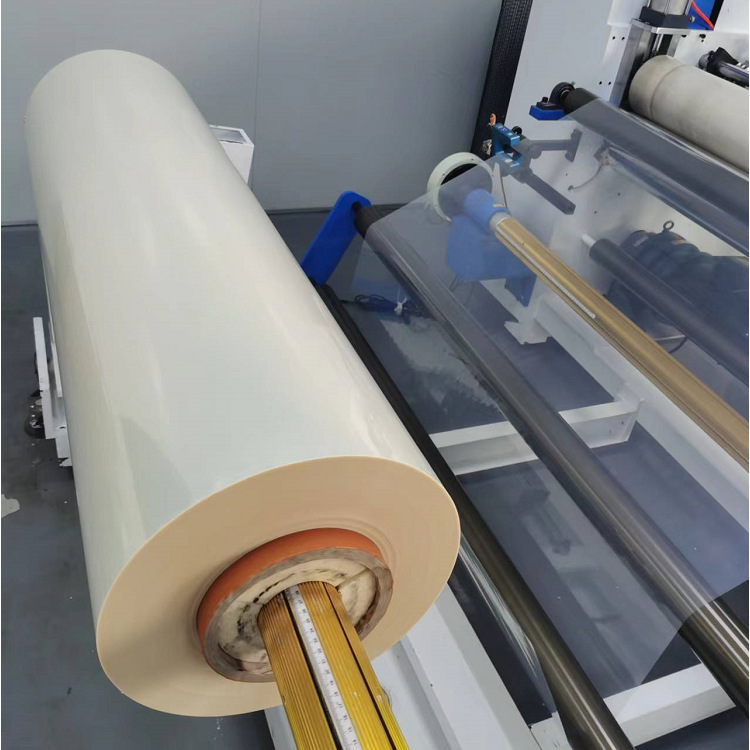

2.PVC film paper finish

Commonly known as blister, MDF is used as the base material, and the surface is affixed with a PVC film. The MDF is smooth and the PVC film is soft. This combination is very suitable for concave and convex modeling. The high-grade film is thick and the texture is realistic. It is often used on the modeling door panel and has become an indispensable door panel craft for European and American styles. A simple understanding is that after the MDF is made into various shapes, and the PVC film is pasted on it, it becomes a blister door. This kind of door is more expensive than the melamine board, mainly on the PVC blister and labor costs. As consumers get younger and more consumers want simplicity, the popularity of this finish is declining rapidly.

3.Baking lacquer finish

Baking lacquer is known as the “king of craftsmanship”. The complexity of the process is much more complicated than that of PVC film lamination. The process of nearly 10 processes is very time-consuming and the success rate is not high. The effect of the products produced by such a complex process is definitely worth looking forward to. Such as high-gloss, matt paint, water-based paint, piano paint, car paint, environmental paint etc, but the high-end and low-end of paint are indeed very different. It is difficult for ordinary consumers to distinguish. Now environmental protection is so strict, and the price of baking paint is becoming more and more popular. Baking paint finishes are generally used to make simple-style door panels, which are the best choice for glass doors. The surface is smooth and easy to maintain. Good waterproof, cabinet doors are also widely used. The disadvantages are: high price, long customization time, easy to spend after hard objects are scratched, irreparable, and most of the white paint will turn yellow after a long time.

4.Solid wood veneer finish

A finish with the highest price and the best texture. A layer of solid wood veneer is pasted on the base material of MDF or particle board, and the surrounding edges are sealed before painting. The solid wood veneer is very thin and the thickness is within 0.6mm, but After all, it is real veneer, and the effect is much more realistic than that of triamine paper and blister film. It has both the texture and texture of solid wood, and the base material is also a board, which avoids the easy cracking characteristics of solid wood itself, and is mostly used in high-end products.

5. Summary

The cabinet generally uses melamine board;

Cabinet doors are available in 4 finishes according to your needs!

Price sort: triamine veneer<blister<baking varnish<solid wood veneer