Nowadays, there are too many materials for home improvement and woodworking, and various types of wood are always confusing. Because there are thousands of raw materials in the raw material market, the same things are also divided into high, medium and low grades, and raw materials with the same function also have different materials. In fact, as long as you understand the characteristics, advantages and disadvantages of these woods, it is very simple to choose the decoration wood suitable for your own. Today, we recommend osb board for everyone. About what osb board is and the advantages and disadvantages of osb board, we will introduce it in detail in the next article. Not only these, we also teaches you how to choose osb board correctly, come and have a look!

What is osb board

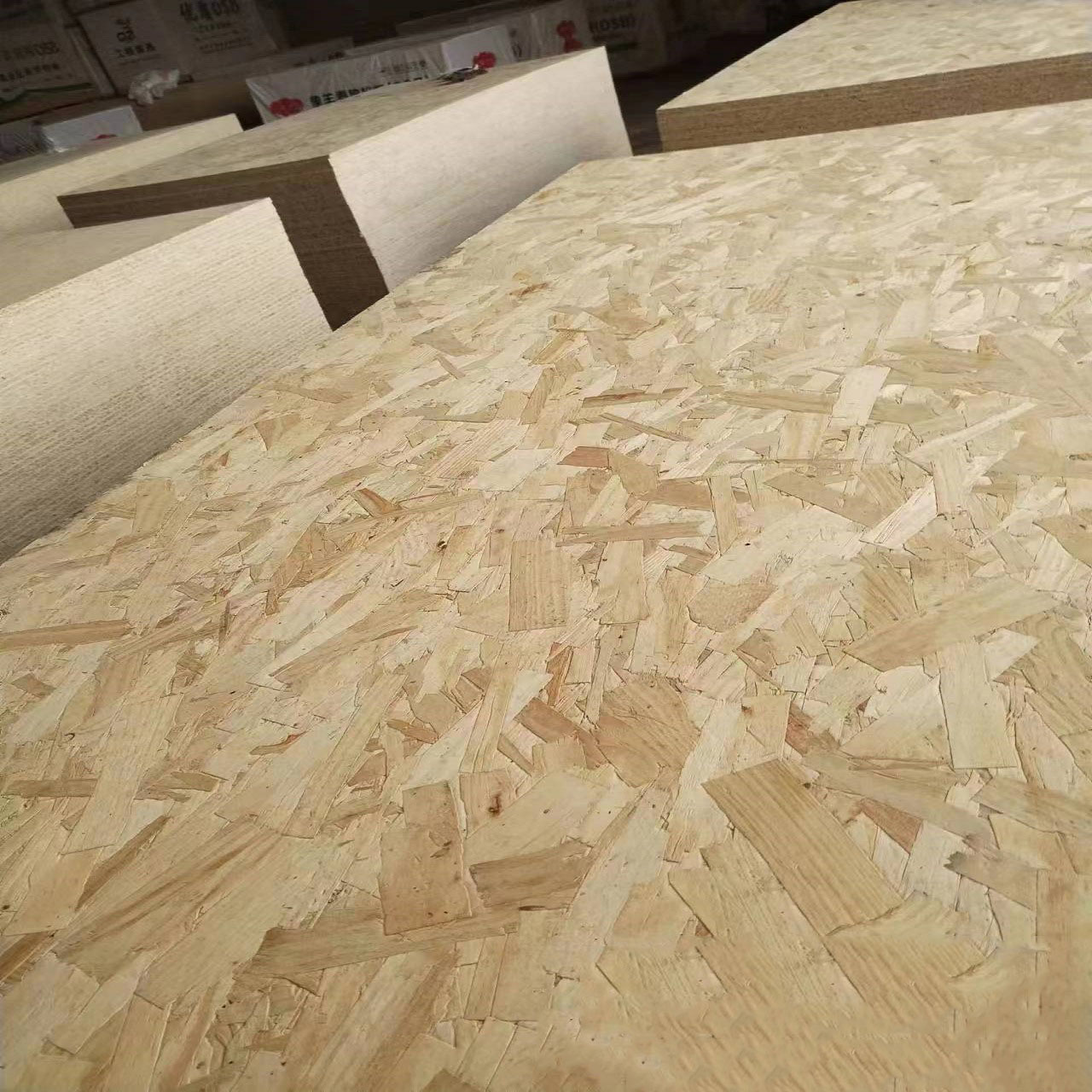

1. The raw materials of osb board are mainly soft needles, small diameter wood of broad-leaved trees, fast-growing thinning wood, etc, such as eucalyptus, fir, poplar thinning wood, etc, which are widely sourced and can be made into large panels (such as 8 × 32 feet) or 12 by 24 feet). The manufacturing process is mainly to dry, sizing, directional pavement and hot-pressing of shavings with a certain geometric shape.

2. The application of “osb board” in furniture has achieved unprecedented development. Many large furniture companies have begun to use “osb board” to make furniture. The reason why it is popular among consumers is that it has low formaldehyde emission and is strong. Durable and lighter than furniture made of medium density fiberboard and particle board (also known as solid wood particle board, melamine board).

3. Osb board is the fastest growing board in the world. It has been widely used in construction, decoration, furniture, packaging and other fields in North America, Europe, Japan and other developed countries. It is an upgraded product of blockboard and plywood.

Advantage

All OSB boards are made of high-grade environmentally friendly adhesives, which meet the highest European environmental standard EN300 standard. The finished product fully conforms to the European E1 standard, and its formaldehyde emission is almost zero. The highest grade decorative board is a real green building material, which fully meets people’s requirements for environmental protection and healthy life now and in the future. The market price of osb board is also comparable to that of high-end large core board, and regardless of environmental performance or physical properties, osb board has comparable goodness. It is closer to blockboard than Australian pine board.

Ingredient structure

It uses small-diameter timber, thinning timber and wood core as raw materials, and is processed into 40-100mm long, 5-20mm wide and 0.3-0.7mm thick shavings by special equipment. It is a kind of oriented structural plate made by processes such as assembly and hot pressing. The surface shavings are arranged vertically, and the core shavings are arranged horizontally. This criss-cross arrangement reorganizes the wood texture structure and completely eliminates the influence of the internal stress of the wood on processing, making it exceptionally easy to process and moisture-proof. Due to the directional structure inside the osb board, no joints, no gaps, and no cracks, the overall uniformity is good, and the internal bonding strength is extremely high, so no matter the center or the edge, it has the super nail holding ability unmatched by ordinary boards. Relying on the kingdom of chemical industry – Germany, Ouban has always maintained a world-leading position in the adhesives used. The formaldehyde emission of the finished products meets the highest European standard (European E1 standard), which is comparable to that of natural wood.