Before purchasing film faced plywood, there are a few things you should consider. These factors include choosing the right supplier, checking for quality, and selecting the thickness and sheet size. Read on to learn more about these factors. You’ll also be able to pick the perfect thickness and sheet size. Read on to learn how to choose the best film faced plywood for your project. Once you’ve made this decision, you’ll have much easier time buying film faced plywood.

Choosing the right supplier

With a demand for plywood so high, it’s easy to find film faced products. Quality Film-Faced Plywood – Ensure your product is made from high-quality material. The film faced plywood you choose should have smooth edges, strong glue joints, and wear-resistant coating. Film faced plywood is durable and will retain its shape for 15-20 years. Additionally, it does not affect the quality of the concrete slabs. Cuzi is an excellent manufacturer of film-faced plywood, offering both structural and non-structural options.

Choosing the right supplier for film faced plywood: There are several factors to consider when choosing a supplier of film faced plywood. First of all, film faced plywood has two different faces. The film faced side is usually coated with an adhesive-impregnated sheet that protects the plywood’s core from water and moisture. Film faced plywood can also be used as a shuttering material for buildings, as well as for formwork and flooring.

Quality Raw Materials – Film Faced Plywood is made using high-quality wood. Its films are resistant to chemicals and fungi, and the veneer has a smooth finish. Its unique bonding strength is an important factor in its durability. A supplier should provide samples to ensure that the product is suitable for its intended purpose. If the customer is not sure about the quality of the material, it may be worth contacting the company to learn about its quality assurance policy.

Checking the quality

If you want to make your project look better, you should know how to check the quality of film faced plywood. The surface of this type of material contains oils, lipids, waxes, tannins and pigments. If you find uneven surfaces on your product, you should immediately send it to a professional for inspection. If the quality of film faced plywood is not good, you can also choose other materials to make your project look better.

Besides being lightweight, film faced plywood is also eco-friendly. It has been meeting expectations of clients for decades. Our company has established itself as a leader in the China manufacturing industry. Its products have a significant place in the construction industry. Its range also includes plywood used in fire-resistant kitchen cabinets. Its professional team of quality control experts performs thorough testing to ensure its quality. If you want to get the best quality film faced plywood, make sure to check its thickness and type of glue.

Film faced plywood is a type of plywood that is used for exterior applications, including ship and boat building. The special melamine glue and film coating protects the wood from water, moisture and abrasion. Because film faces are so durable, it improves the life span of the product. Moreover, the material is lightweight, firm and undefected, making it ideal for use as formwork. You can reuse this type of plywood several times.

Glue plays a crucial role in the composition of the plywood. In general, manufacturers use WBP (Waterproof), phenolic or melamine glue. You can check the quality of film faced plywood by applying a boiling water test. This test helps you determine whether the film is still intact after the glue has been applied. It also determines how strong it is by allowing the glue to penetrate the plywood’s surface.

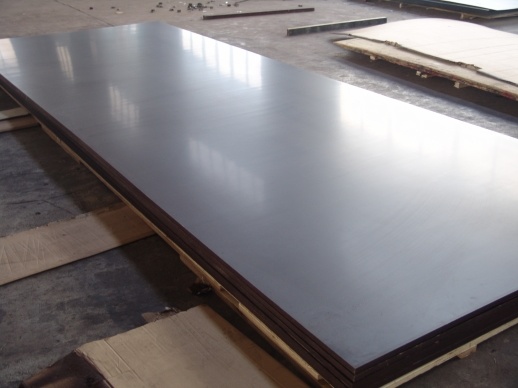

The film faced plywood is usually available in standard sizes, but some suppliers may offer customized sizes to fit your project. The most common sizes of film faced plywood are 1220x2440mm and 910x1820mm. You can purchase film faced plywood in either plain or with your logo printed on it. Depending on the film’s adhesion, the film will affect the durability of the product and its aesthetics.

Choosing the right thickness

Choosing the right thickness of film faced plywood is important for many reasons. For example, if you are building a table, an 18 to 24mm sheet will be perfect. For a set of drawers, you might want to use 6 and 12 mm plywood sheets. Ultimately, the thickness of the plywood you use will depend on your intended use, but there are some factors that should be considered. Thickness will be important if the piece is going to be sturdy. Thinner sheets are best for decorative pieces, so the decision is largely up to you.

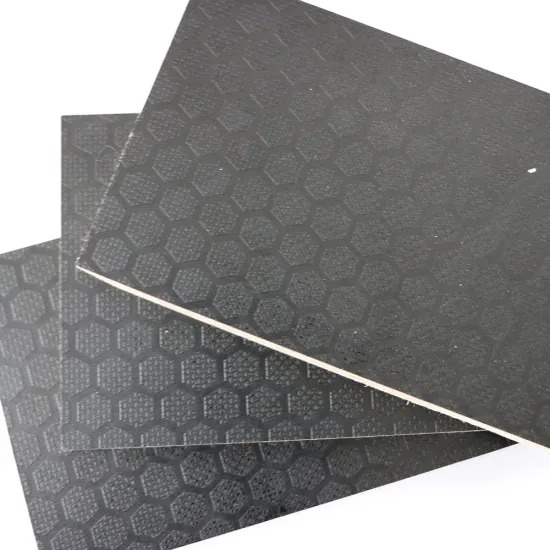

Considering its durability and sturdiness, film faced plywood is an excellent choice for outdoor or indoor applications. You can choose from a variety of colors, including bright and dark colors, and even grainy, textured surfaces. You can also select an anti-slip film faced plywood. It is often used for boat decks, platforms, and other outdoor structures. Film faced plywood is available in different thicknesses, including two-thirds, four-inch, and eight-inch.

Before purchasing film-faced plywood, be sure to check the grade and the appearance of the material. The wood grain in film faced plywood should be clean and free of defects such as damage, scars, and degumming. If you’re unsure about the quality of the film, talk to the salesman to find out which one is better for your needs. For example, if you’re looking for a thick, durable board for a kitchen, you may want to buy a brown or black film faced plywood.

Choosing the right thickness of film faced plywood for a concrete slab is essential to the success of your project. Make sure that the edges are painted and protected for added strength. Film faced plywood is a strong base material that’s resistant to water, UV rays, and degrading chemicals. It also helps to smooth out the surface of the concrete and adjust the drying process. These benefits make it a popular choice for concrete construction.

A few other considerations are important for film-faced plywood. Besides the thickness of the veneer, the dimensions of the plywood sheet are also important. A smaller thickness will make it difficult to install the plywood sheet correctly. For instance, the thickness of the film facing plywood should be smaller than the dimensions of the plywood sheet. It should be a minimum of 1290 mm and a maximum of 2550 mm.

Choosing the right sheet size

When shopping for film faced plywood, you’ll want to choose the right sheet size for your project. This type of plywood is also known as concrete form ply or shuttering plywood. There are some important things you need to know about this product before purchasing it. Below are some tips for selecting the correct sheet size for your project. Choosing the right sheet size is important for a variety of reasons, so it’s crucial to know what you’re looking for and how to select it properly.

When shopping for film faced plywood, make sure you’re looking for one that has a 1220x2440mm sheet size. This type of sheet is easy to clean, since it’s smooth. Also, make sure there are no glue spots on the sheet, as this will cause the board to lose its water-resistance properties. Finally, choose the right sheet size if you’re unsure of the final appearance of the board.

While manufacturers strive to get the thickness of their film faced plywood as close as possible, they can’t guarantee it. Some thicknesses may be more or less than others, depending on how the plywood was processed. Choosing the right sheet size is an essential consideration if you’re using this product for a project where the thickness is crucial. A thin sheet can flex, so make sure you choose the right sheet size.

If you’re not sure what sheet size you need, make sure to try several on a piece of plywood first before purchasing a large sheet of plywood. You can make test cuts and see if it fits well. It’s always best to go with a slightly thicker sheet to ensure that it won’t rip or tear during installation. For more accurate sheet sizes, you can also measure the overall thickness of your project, which can help you determine which sheet size to purchase.

When shopping for film faced plywood, choose the correct thickness. Remember, not all plywood is the same thickness. For example, a 3/4-inch sheet of plywood can actually be 23/32 inches thick. That’s a small gap, and a recessed panel that’s 1/31 inch thick won’t look too great. Luckily, there are a variety of different sheet sizes available in home improvement stores, so you don’t have to settle for a size that doesn’t fit your project.