Whether you are looking for veneer for your next project, or are looking for more information on the many uses of veneer plywood, there are some essential pieces of knowledge that you must have. Listed below are some of the most important facts about veneer plywood: Decorative uses, Grades, Cost, and Spliced veneer face. In addition, this article covers splicing methods to make them look more appealing, and the types of adhesives that are used in veneer plywood.

Decorative uses

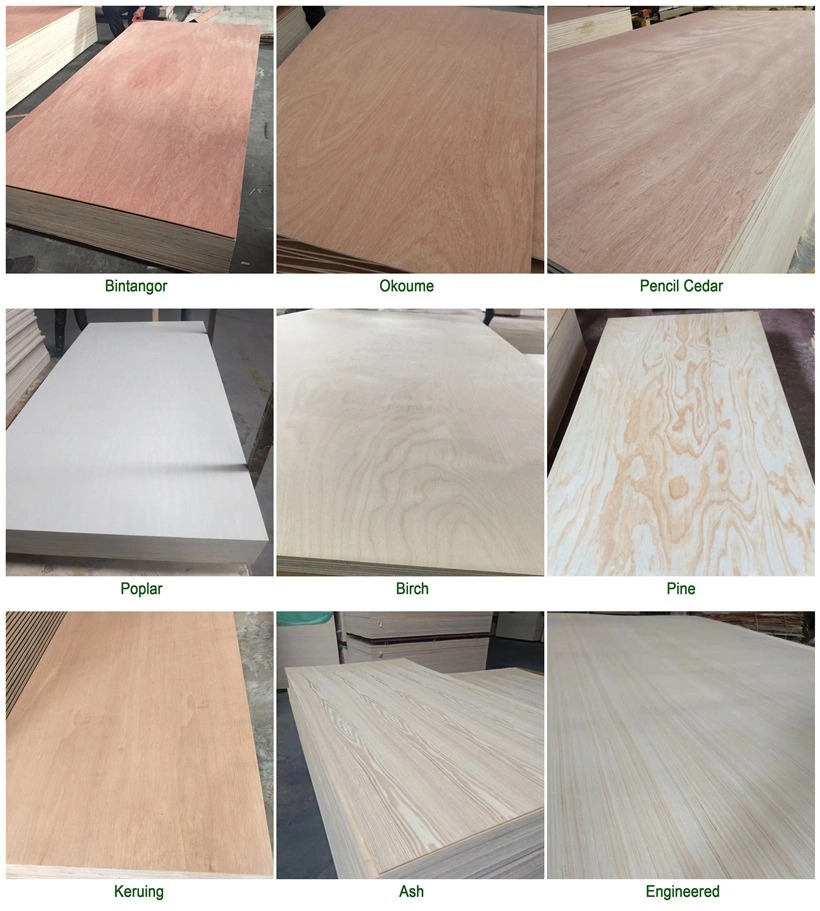

Decorative uses of veneer plywood are plentiful and varied, from furniture to home decor. The face veneer of a plywood panel has a unique grain and texture, which is reflected in its grade. This type of veneer is generally more expensive than chipboard, but is a more environmentally friendly alternative to solid wood. It also allows designers to maximize the use of rare, aged woods and offer sophisticated pattern designs. Decorative uses of veneer plywood include cabinetry, countertops, and more.

The earliest recorded use of plywood is in ancient Egypt, when a coffin made of a type of veneer was discovered. Images of workers cutting the veneer with an axe-like tool and preparing glue in a pot on fire were discovered. Egyptian tombs also contained furniture made of overlapping sheets of wood with inlay. The ancients preferred the look of hardwood veneer due to its attractive shade and texture. The introduction of plywood, however, was linked to the high price of wood.

While the beauty of real wood can never be duplicated, veneer sheets can add charm to any project. Decorative uses of veneer plywood include everything from art work to collectors’ items. They are a beautiful way to enhance the interior of any room and make it more memorable. However, you may not know what to use it for, but the possibilities are endless. So, how can you maximize the decorative uses of veneer plywood? There are several different types available in the market.

There are two types of veneer available: raw and reconstituted. Raw veneer is the cheapest and is made of sheets. The other type is a composite that is made of multiple sliced blocks. In contrast, laid up veneer is made from raw pieces. It is easier to work with if you need to cover a large area with veneer. Decorative uses of veneer plywood

Grades available

There are four common grades of veneer plywood: A, B, C, and D. Each grade reflects the quality of the veneer on one or both sides of the panel. Grade A, which is the best quality, is the most expensive. It is smooth and has virtually no defects, while grade B has minor imperfections, including knots and filler. This grade is perfect for use as a decorative surface in homes, office buildings, retail outlets, and community venues.

“AAAA” grade: This grade is the highest quality veneer available in the market. It contains minimal pin knots and mineral streaks, but may have some defects. “AAAA” grade veneer is typically eight inches to 12 inches long with very tight burl and close grain and color. There are fewer splices in this grade, but the veneer may contain moderate figure breaks. If you’re working on a budget, this grade is ideal.

Marine: Marine plywood is made from core veneers. It has a higher-quality face and can resist delamination and fungal attacks. Its veneers are made from tropical hardwoods, including Douglas fir and western larch. Its unique core gap is minimal, so water cannot get into the plywood and create a crack. The glue bond is also stable. There are several types of veneer plywood available. If you’re looking for a veneer plywood, Austim carries a variety of products.

There are many different grades of veneer plywood. The most common are plain-sliced, A1 and B1 panels. These grades are designed to mimic the look of solid lumber, with a uniform grain and color. They are commonly used in cabinet doors and fine furniture. These grades are generally expensive, so it’s worth it to invest in the best veneer you can afford. However, these veneers will have to be carefully selected for your needs.

Cost

The cost of veneer plywood varies according to its quality and brand. It can be as low as 80 cents per square foot or as expensive as $150. When using veneer plywood for home renovation projects, it is best to avoid cheap products, as they may contain splintering. If you are working on a DIY project, you can use the wood patch method to repair damaged wood. Alternatively, you can use a table saw or bandsaw to cut the wood patch.

There are two types of veneer: reconstituted veneer, which is made from sliced blocks with no backing, and raw veneer. Paper-backed veneer is the most common type, although phenolic backed veneer is preferable for composite and curved products. Wood-on-wood veneer has the opposite direction to the face veneer. It is cheaper to purchase than parallel-grain veneer, but there are some differences. You will need to consider the direction of the grain of the face veneer when determining the cost of veneer plywood.

Veneer plywood has a long history in the construction industry. It dates back to the 1850s and is made from alternating layers of wood. It is used in construction for furniture, cabinets, and more. Its durability has made it an increasingly popular choice in many applications. For example, aircraft plywood is lightweight, flexible, and strong. It is also used in heavy-duty projects, and originally, aircraft plywood was used in fighter aircraft.

Wood-based veneer plywood is often the least expensive option, but the quality can be quite good. Its durability makes it ideal for outdoor applications, where the climate is dry and harsh. The plywood is made of different types of wood, including hardwoods, which are good choices for climates that tend to be harsh, as they resist mold and mildew. These types are available in DIY stores and are easy to cut and process. So, whether you’re building a new house or renovating an old one, wood-based veneer plywood is likely to be a better option.

Spliced veneer face

Spliced veneer faces are sheets of wood joined together with a matching effect. Veneer sheets are made in a factory using tapeless splicing. One type of veneer is stump veneer. The wood has swirly twisted grain patterns. They may also have patches of burl and crossfire. Generally, these veneers are small in size. However, they may vary in color and texture.

A common manufacturing defect is called a lap. This happens when a section of veneer overlaps itself or splits because of uneven moisture movement. These small checks may be shaped like a split or resemble a press dent. They may be visible through the face or back veneer. If you notice a lamination, you may have to sand the veneer to get rid of it. If the check is small, the wood isn’t solid and may show through the face or back.

The first step in separating a veneer is to understand how it is arranged. A veneer face is made up of components that run through the flitch consecutively. The leaves are the ones starting the next panel. Sapwood is lighter in color and thinner than heartwood. Different species of wood have different sapwood thickness. A veneer face is grouped according to its grade, known as a flitch. When the veneer faces are arranged according to their relative positions on the tree, they have similar grain and figures.

A higher-grade face is matched with lower grade veneer. The adjacent components appear dark or light in color, and the lathe checks absorb the finishing material. A higher-grade veneer face has no noticeable bark areas. It is impossible to tell from a distance whether the two face veneers are joined together unless you know which component is darker or lighter. In any case, it is essential to understand how each component fits together.

Face-checking in veneered plywood

Wood veneered plywood may have face-checking along the grain. This effect is greater on the face veneer side than the core, and can be minimized by applying a clear film-forming finish. Face veneer-checking was studied in 15 different plywood panels: one with a tight-side-out lathe check orientation, one with a loose-side-out lathe check orientation, and a mixture of both. After tensile testing in a hot-dry chamber, the panels were visually inspected.

Veneer-checking occurs when wood across the grain shrinks and expands in response to changes in moisture content. The veneer faces can swell and shrink with the changes in MC, creating greater stresses and risk of wood failure. The most important factor in preventing veneer checks is controlling moisture content. Veneer checks occur when the face of the veneer shrinks compared to the core, and the degree of checking is directly proportional to the amount of shrinkage.

Surface checking is most likely to occur in 3 ply veneered plywood than in five ply. However, 5 ply veneered plywood panels contain a cross band that helps counter the stresses set during the drying of face veneer. Another factor that determines surface checking is the pressing method. Hot or cold pressing may result in more surface checking. Hot pressing, on the other hand, eliminates a higher percentage of moisture from the veneer.

Face-checking is an inevitable condition in veneered plywood, as it results from the loss of moisture from the panel core. The size of these checks depends on the moisture content of the face veneer, which is usually different from the panel core and existing EMC. In the event of a check, the face veneer is exposed to stress that can cause fibers to loosen. In addition to this, the thickness and appearance of veneered plywood can vary widely.