Veneer is widely used in the veneer decoration of furniture and other products. It is a thin wood veneer or veneer material with the characteristics of precious tree species.

The earliest use of veneer found so far was in Egypt 4,000 years ago. Due to the tropical desert climate, wood resources were scarce, but the ruling class was very fond of precious wood. Under this circumstance, craftsmen invented the cutting of wood.

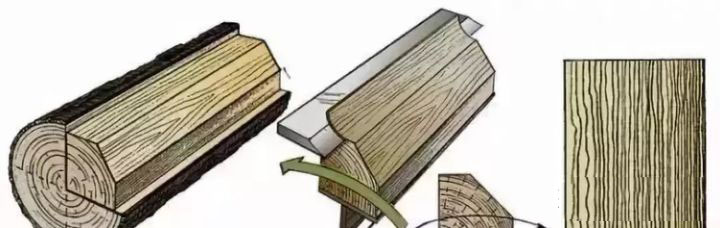

How veneer is made

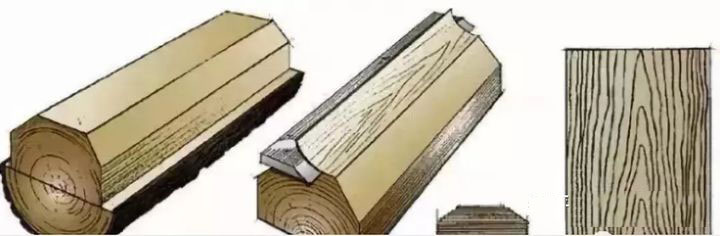

From the perspective of production methods, veneer can be divided into chord cutting, radial cutting, rotary cutting and cutting material cutting. Different cutting methods produce different veneer texture and veneer structure.

Chord cut

Plain Slicing, Flat cut , a slicing veneer means that a slicing knife runs along a parallel line in the center of the log, cutting out the wood pieces.

The chord-cut veneer is cut from the bisected log, and the growth rings of the most entering layer will form a “cathedral” pattern wood grain.

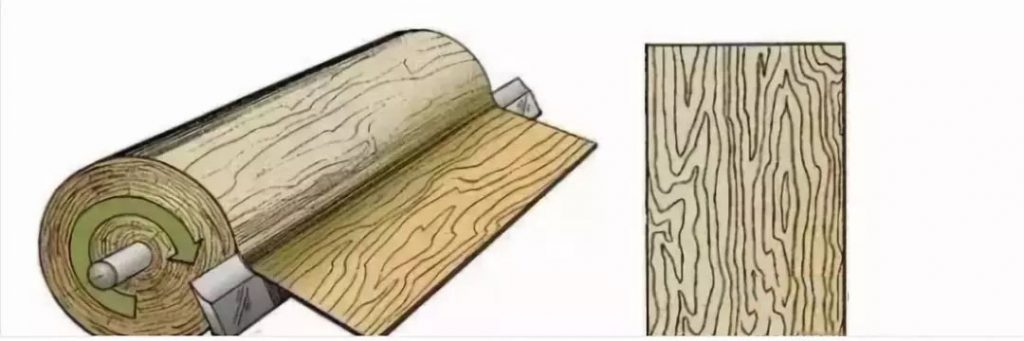

Rotary Cut

Rotary Cut – The log is installed in the center of the lathe, the slicing knife is inserted into the log at a slight angle, and the log is rotated against the slicing knife to create a rotary cut veneer. Rotary cut veneer can be wide enough to provide a whole board (single) board surface.

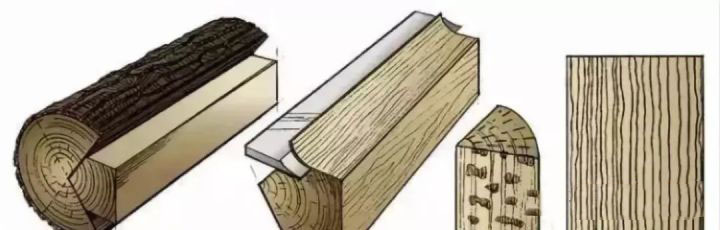

Quarter Slicing

Quarter Slicing – Quarter Slicing is the vertical slicing of the growth rings of a log, producing a veneer that exhibits a straight grain.

Rift-Cut

Rift-Cut – Rift-cut veneer made from various oaks. The pith rays of oak extend from the center of the log, like the curved spokes of a wheel. Cut the pith rays of the oak at a slight angle to minimize the appearance of “scale”-like wood grains and produce a straight-grained veneer.

Types of veneers

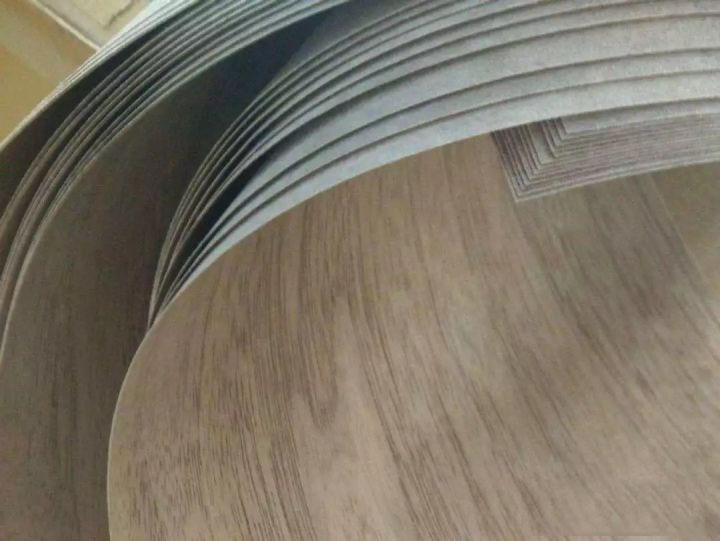

The charm of veneer lies in its unique wood grain, rich and beautiful colors, and natural beauty. The rigorous production process to make natural veneer adds a different value to it.

Natural veneer

It has the natural and simple fragrance of wood, full of texture, and its special and irregular natural texture has a superb and ingenious artistic charm, which can bring people the original heart of returning to nature and the artistic enjoyment of beauty.

Natural veneer is widely used: thin veneer is used for the production of veneer, cardboard and non-woven veneer; thick veneer is used for veneer parquet, furniture production, laminate floor veneer.

Technology veneer

Using the principle of bionics, high-tech processing of ordinary fast-growing wood, and reorganization and beautification are used to make new wood materials with better performance. The film made of technical wood is generally called technical veneer.

The technical veneer has the characteristics of rich luster, various varieties, great product development potential, large decorative size and convenient processing.

Stained veneer

A new type of decorative material made by using high-tech processing technology to process and color natural wood defects, commonly known as dyed wood in China, and the veneer processed from dyed wood is called dyed veneer.

Stained veneer has the characteristics of natural texture, zero surface defects and green environmental protection.