- 1.What is lifting building formwork?

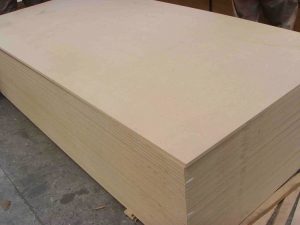

A: Lifting construction formwork is a kind of tool type formwork for building double curve cooling tower, chimney and other projects. It is composed of steel derrick, lifting table,concrete form plywood,formwork and lifting equipment etc.

- 2.What is the combination type building formwork?

A: Combined construction formwork, is a modern formwork, with strong versatility, easy to dismantle, turnover more than one “steel instead of plywood” of the new concrete shuttering plywood for formwork, with it for cast-in-place concrete structure construction, can be assembled in advance according to the design requirements into beams, columns, walls, floor slabs of large formwork, the whole lifting in place, but also using loose dismantling method.

- 3.What requirements should the construction plywood for formwork installation meet?

Formwork plywood installation should meet the following requirements:

1) The joints of the formwork should not leak; before pouring concrete should be watered and moistened, but there should be no water in the phenolic film faced plywood;

2) The contact surface of the formwork and concrete should be cleaned and painted with isolating agent, but shall not use the isolating agent that affects the function of the structure or hinders the construction of decorative works;

3) Before pouring concrete, the debris in the plywood for construction formwork should be cleaned;

4) For clear concrete works and decorative concrete works, the formwork should be used to achieve the design effect.

- 4.What are the requirements for the arching of cast-in-place concrete beams and slabs when building formwork is supported?

A: The plywood for formwork specification stipulates that for cast-in-place concrete beams and slabs with a span of not less than 4m, the building waterproof plywood for shuttering should be arched according to the design requirements; when the design does not have specific requirements, the height of the arch should be 1/1000~3/1000 of the span.concrete form plywood suppliers near me.

- 5.What are the requirements for dismantling the building formwork of post-tensioned prestressed concrete structure?

A: For post-tensioned prestressed concrete members, the side modules should be dismantled before prestressing tensioning; the dismantling of plywood formwork for concrete brackets should be carried out in accordance with the construction technology plan, and should not be dismantled before the establishment of prestressing in the structural members when there is no specific requirement and formwork plywood for sale.

- 6.Building plywood of concrete form plywood suppliers for concrete should be prepared before installation?

A: Construction mdo form plywood should be done before installation: 1), to the construction team to do a good job of construction briefing, and make a sample, approved by the supervisor and relevant personnel, in a large area; 2), support the pillar of the soil ground, should be tamped and leveled in advance, and do a good job of waterproofing, drainage settings, prepare the pillar ground mat; 3), plywood formed concrete installation of the bottom surface should be smooth and solid, and take reliable positioning measures, according to the requirements of the construction organization design pre-buried Support anchorages; 4), the shuttering plywood jewson should be painted with release agent.

- 7.Construction types of plywood for formwork support installation should comply with those provisions?

A:Shuttering plywood sheets support installation should comply with the following provisions: 1), according to the design of the formwork in order to ensure the overall stability of the formwork system; 2), accessories must be installed and inserted firmly. The support surface of the support and diagonal support should be flat and solid, and there should be enough pressure area. 3), pre-buried parts and reserved holes must be accurately positioned and firmly installed; 4), the grass-roots formwork must be firmly supported to prevent deformation, the bottom of the oblique support of the side mold should be added to the pad; 5), the bottom surface of the wall and column formwork should be leveled, the lower end should be close to the pad level with the positioning benchmark made in advance, when the wall and column continue to install the formwork, the formwork should have a reliable support point, and its straightness should be corrected; 6), the floor plywood used for formwork support formwork the horizontal support and diagonal bracing of a frame should be completed first, and then gradually expanded outward to maintain the stability of the system; 7), pre-assembled strong template lifting in place, the lower end should be padded, close to the positioning benchmark; both sides of the template should use diagonal bracing to adjust and fix its verticality; 8), the horizontal bracing and scissor bracing set by the pillar, should be arranged according to the structure and overall stability; 9), multi-layer support pillar, the upper and lower should be set in the same Vertical center line, on the lower floor should have the bearing capacity to withstand the load of the upper floor or additional support. The column of the lower support should be laid with a mat.

- 8.What concrete form ply matters should be noted when removing the construction best quality shuttering plywood?

A: 1) The construction formwork should be carried out in accordance with the provisions of the plate design, follow the first support after demolition, first non-load-bearing parts, after the load-bearing parts and the top-down principle. Demolition, forbid the use of sledgehammer and crowbar hard smash hard pry; 2), first remove the side mold, in the removal of load-bearing mold; 3), the combination of large ply formwork should be removed as a whole; 4), the support and connection should be disassembled piece by piece, the template should be disassembled and passed piece by piece, forbidden to throw overhead, demolition shall not damage the formwork and concrete; 5, the template removal should pay attention to construction safety, strict construction safety requirements and the requirements of the formwork construction program for safety protection .

- 9.Construction of construction formwork should pay attention to those safety requirements?

A: The safety requirements of formwork construction are: 1. When installing and dismantling the pre-assembled block formwork, two lifting points should be used for vertical lifting, and four lifting points should be used for horizontal lifting. Installation should be on the side for, while correction and installation of the connection. Only after the connection is firm can the hook be removed. When lifting scattered formwork, the formwork should be put in the cage to prevent falling and injuring people; 2、No open fire welding and cutting work should be done in the formwork stacking site and construction site. If welding and cutting must be carried out, there should be reliable fire-fighting measures; 3、When pouring concrete, there should be someone to look after the formwork. If the formwork tilts, displacement, local bulging, running mold, should take timely tightening measures before continuing construction; 4, demolition of the mold, should be dismantled piece by piece, not piece pry down or pull down. The dismantled formwork, accessories, is strictly prohibited to throw, to have a person to pass, according to the designated place stacked.

- 10.What is climbing construction formwork?

A: Climbing construction selco shuttering ply formwork (climbing formwork) is a formwork process suitable for the construction of vertical or inclined structures of existing reinforced concrete, such as walls, bridges, towers and columns. It can be divided into “climbing cost of shuttering ply with frame” (i.e. formwork climbing frame, frame climbing formwork) and climbing formwork without frame (and formwork climbing formwork) two kinds construction formwork construction records summary.

1) The operator must hang and fasten the safety belt when dismantling the construction concrete form ply.

2)The relevant scaffolding must be erected before supporting the construction formwork (see the scaffolding plan and related plan of this project, relevant safety operation procedures, etc.).

3)No scaffolding is allowed to be dismantled before demolition of wall formwork, when demolishing with tower crane, cooperate with heavy lifters; demolish the top building formwork before delineating the safety area and safety channel, close the non-safety channel with steel pipe and safety net, hang the safety sign of “No M Passage”, operators are not allowed to be in this area, they must operate on the operation frame with a springboard.

4) When plywood formed concrete, make the formwork inclined downward by 30°, and do not stack the formwork on the construction layer to prevent the formwork from overturning under the wind load.

5)The large formwork stacking site must be hardened, level and enclosed, and the construction plywood home depot corner moulds are placed on a small enclosing frame. After installation in place, to take measures to prevent electric shock protection, the large template will be connected in series and connected with the lightning network to prevent leakage injuries.

6) Before pouring concrete, check whether the support is reliable and whether the fasteners are loose. C pouring concrete must be set up by the formwork support team to watch the mold, at any time to check whether the support is deformed, loose, and organize timely restoration.

7) Woodworking machinery must strictly use the inverted switch and special switch box, the primary line must not exceed 3m, the shell connected to the protective zero line, and well insulated. Chainsaw and electric planer must be connected with leakage protector, saw blade must not have cracks (check before use, check at any time in use); and chainsaw must have a belt guard, saw blade guard, divider and hand guard device. The use of ply for shuttering multi-purpose machinery is strictly prohibited at the same time the use of chainsaw and electric planer; use of cost of shuttering ply machinery is strictly prohibited to wear gloves; length less than 50cm or thickness greater than the radius of the saw blade of the black shuttering plywood is strictly prohibited to use chainsaw; two people building operation with each other, white film faced plywood shall not pull hard; machinery out of use when the power off and lock.

8) when using the tower crane to lift the template, must be directed by the heavy industry, strictly comply with the relevant safety operating procedures.

Formwork installation in place before the need to have cable pull, to prevent the template rotation is not good to hit people; vertical lifting must take more than two lifting points, and must use the card ring lifting. It is not allowed to lift two pieces of formwork at one time.

9) When phenol film 12mm construction work is carried out in the elevator room, a safety protection platform must be set up layer by layer. Because the shuttering plywood sheets side force of concrete is affected by both temperature and pouring speed, so when the construction temperature is high in summer, the pouring speed of concrete can be increased appropriately, and the pouring speed of concrete should be reduced appropriately in autumn and winter when the construction temperature decreases. When medium T=16℃, the waterproof plywood for shuttering pouring speed is not greater than.